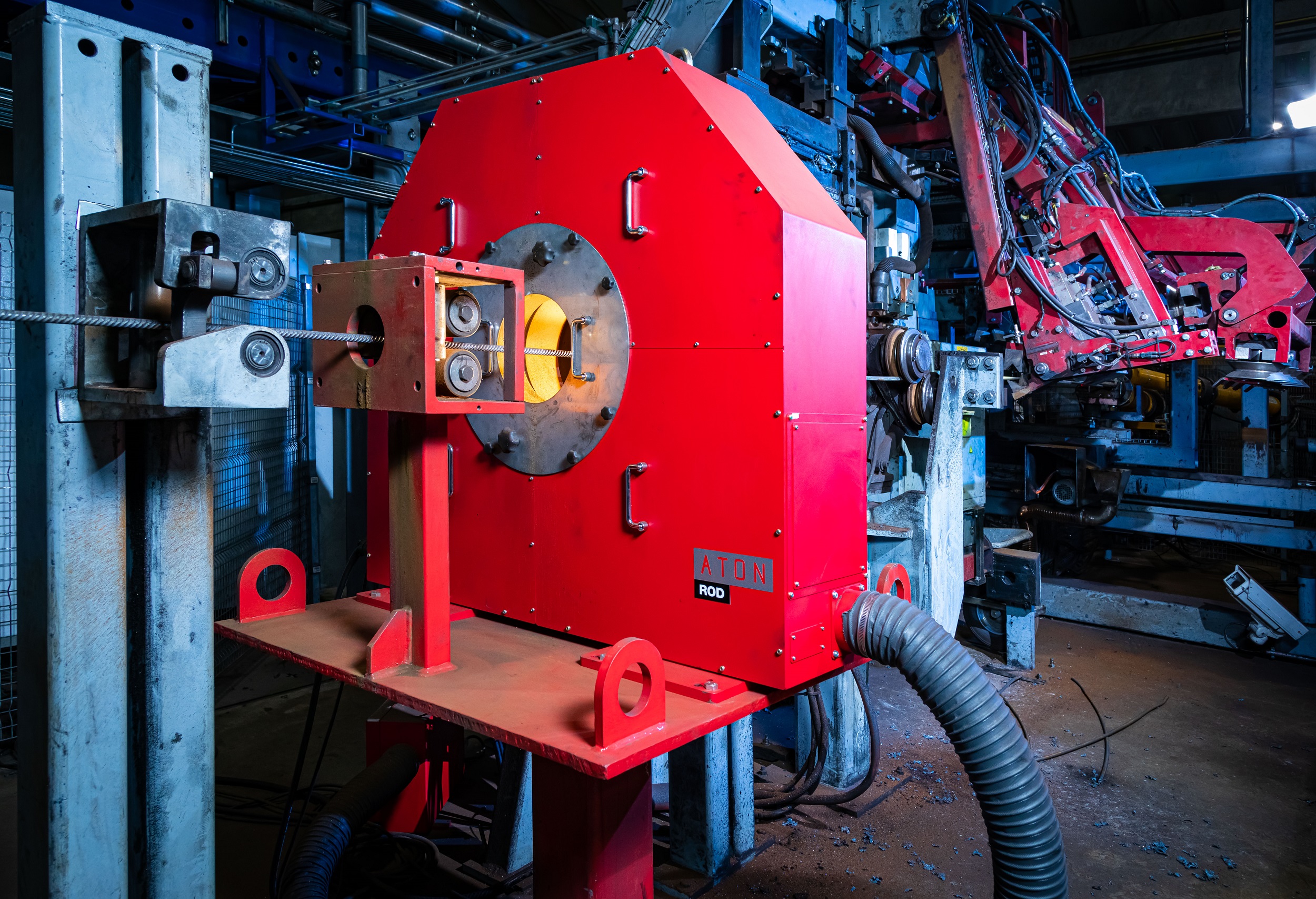

Precisely measure where others are simply guessing

Our non-contact measuring systems are based on a patented development of laser light section technology. No matter who uses them, you will always have accurate results – without any application errors, incorrect readings or making any assumptions. Tamper-proof data transmission.

contact us